The pipe sizing methodology described in the SBC is optional due to the variable conditions encountered in the hydraulic design. Accordingly, other sizing or design methods conforming to good engineering practice standards are acceptable alternatives. Below is an example using a population of 4,964 to demonstrate that the optional methodology in SBC is exaggerated. Since the CIPHE/IoP methodology has been used successfully on numerous projects without oversizing, the SBC and IoP methods will be compared in this article to establish the most appropriate method.

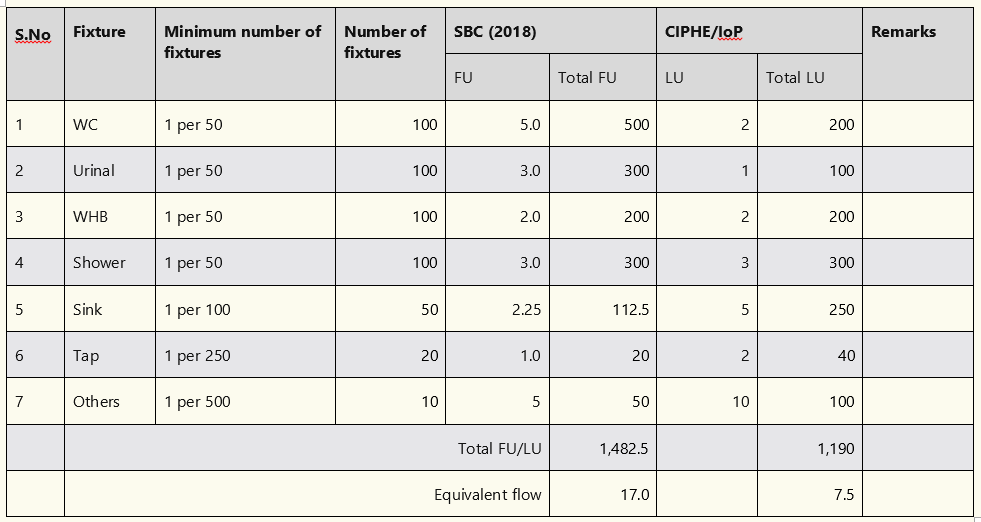

Based on an occupancy of 4,964 people, the minimum number of sanitary fixtures, in accordance with SBC 201 (2018), will be as tabled below. The only columns that require input are 4,6 and 8. The equivalent flow based on SBC and CIPHE can be determined. From the example below, it can be seen that the equivalent flow is 133% more if the SBC method is used.

Based on a flow rate of 0.1 l/s for the WHB, urinal and WC, the SBC (2018) optional method shows that more than 50% of the WHB, Urinal and WC will be in use at the same time which is unlikely. The CIPHE/IoP method shows that about 25% of the appliances will be in use at the same time. Therefore, the CIPHE/IoP method is more suitable for this project.

The disadvantages of the SBC method are.

- Increased pipe size.

- Increased pipe insulation. `

- Less space in ceilings and risers.

- Increased pipe supports.

- Increased load on the building.

- Increased storage space.

- Longer installation time.

- Oversized pump set which leads to:

a) Higher energy consumption: Oversized pumps often operate at less optimal points on their performance curves, resulting in higher energy consumption. This inefficiency can lead to increased operational costs over the long term.

b) Increase Maintenance Costs: Larger pumps generally require more maintenance. Oversized pumps operating at lower capacities may experience increased wear and tear due to issues such as vibration, which can result in higher maintenance costs over time.

c) Noise and Vibrations: Larger pumps can produce more noise and vibration during operation. This can lead to discomfort for personnel working in the vicinity and may require additional measures, such as soundproofing or vibration isolation, to mitigate these effects.

d) Water Hammer: Oversized pumps can contribute to water hammer issues in the system. Water hammer occurs when there are rapid changes in fluid velocity, leading to pressure spikes that can cause damage to pipes, valves, and other components.

e) Difficulty in control: Oversized pumps can be more challenging to control, especially if the system experiences varying demand. Maintaining stable system pressure becomes more difficult when the pump capacity significantly exceeds the actual demand.

f) Potential for cavitation: As mentioned earlier, operating pumps at very low capacities can lead to cavitation, a phenomenon where vapor bubbles form and collapse within the pump, causing damage to the impeller and reducing pump efficiency.

g) Wasted resources: Oversizing a booster pump can result in a system that has more capacity than necessary for typical operating conditions. This excess capacity may represent wasted resources in terms of both energy and equipment.

h) Design Complexity: Designing and implementing systems with oversized pumps can introduce complexity in terms of hydraulic analysis, control strategies, and safety measures. This complexity can make the system more challenging to design, commission, and maintain.

i) Potential for water quality issues: If the flow rate through the system is too low, there may be insufficient water turnover, potentially leading to issues related to water quality, such as stagnation or the buildup of contaminants.

j) Reduced pump life.

9) Considerable increased installation and operational costs due to bigger pipe sizes, insulation, pipe supports, storage, and all the above points.

10) No options for low, medium, and high frequency use selection.

Visit us at pmt-me.com to explore our growing repository of research, technical articles, product reviews, and expert interviews. We look forward to your feedback and to continuing the conversation about the future of public health engineering.

2 Responses

One more (-ve) to add, in practice, the larger pipe sizes may not allow the sewer to reach the required self cleaning velocity, which can cause deposition or accumulation of particles along the drain length!!

Nice comparison, would love to see a similar one on Sanitary Drainage pipe sizing