Ashveen Jeetun BEng(Hons), MSc, CEng, FCIBSE, FCIPHE, MSoPHE

Building Services Engineering, BuroHappold

Honorary Treasurer, CIBSE UAE

Technical Committee Member, CIBSE UAE

Abstract

With almost one hundred and seventy five million cases of SAR-CoV-2 and almost four million deaths registered worldwide, governments around the world introduced drastic measures to reduce the spread of the disease. It is essential to improve the design of buildings to reduce the risk of disease transmission.

It is common that water treatment in potable water supply is provided, but the drainage system is rarely considered. Drainage traps can become a reservoir of pathogens. Bioaerosol is then released into the surrounding air when water flows through the trap. In 2003, the drainage system was found to be the cause of the SARS coronavirus outbreak at Amoy’s garden residential complex, Hong Kong, where 329 residents were infected and 42 died. Pathogens Management Train (PMT) is a new concept that uses existing scientific research methods to identify the exposure pathways to pathogens at all stages of the public health engineering cycle. This paper proposes new and existing procedures to improve the design public health engineering design to mitigate the risk of disease transmission. The PMT can be used against all types of pathogens including bacteria, parasite and virus.

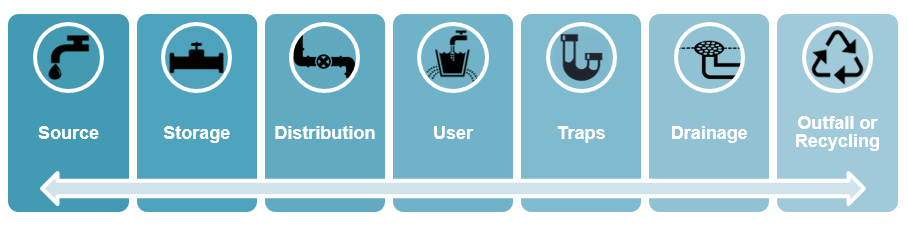

The PMT, illustrated in Figure 1, identifies seven stages where considerations should be given. The stages consist of Source (stage one), Storage (stage two), Distribution (stage three), Use (stage four), Traps (stage five), Drainage (stage six) and Recycling or Outfall (stage seven).

The risk of transmission of disease can be efficiently reduced by using PMT as a concept to design a public health engineering design.

Figure 1 – Pathogens Management Train Stage in Public Health Engineering Systems

Keywords Pathogens Management Train, Plumbing, Biofilm, Bioaerosol, Drainage

1.0 Introduction

Inadequate public health engineering installation can be a contributor to the spread of pathogens. The risks exist at all stages of the plumbing cycle right from the connection to the Water Supply Company network to the final discharge into the public sewer or wastewater treatment plant.

The transmission of pathogens into the plumbing system can occur by ingress into the system from contaminated environment like water pipes in contaminated soil. Cross-connection of potable water with recycled water can also be a cause of contamination. Aerosol from odour traps, viral shedding in faecal matter and/or backflow into the system are other ways that pathogens can be transmitted into the public health engineering systems.

Some of the most common transmission routes, including but not limited to inhalation, incidental ingestion, dermal contact, ocular, oral mucus membrane contact and faecal-oral should be considered when designing a public health engineering system. These transmission modes can occur through both direct or indirect contact with contaminated water from the water supply and/or the sanitary drainage system. Direct contact can happen when bathing, washing, drinking contaminated water. Indirect contact occurs mainly through the formation of bioaerosol from the water supply or sanitary drainage systems. Immunocompromised people, the elderly, people with dominant diseases, such as cancer and other patients after organ transplants are particularly at risk. The current design of sanitation facilities is not adapted to this large and growing group of vulnerable people.

Imbalance of residual chlorine level is a problem on large projects where storage tanks are provided. On-site treatment is usually required. Several technologies are available, but it is important to select the most appropriate solution for the project by considering several factors such as temperature, volume, disinfection, etc.

Even with source treatment, formation of biofilm can still occur if water in some sections of system, downstream the water storage tank, is stagnant. Planktonic cells can attach and develop into sessile cells to attach to surfaces of pipes. As the colonies mature, detachment of planktonic cell occurs to contaminate other places into the system. Therefore, the PMT considers the risks of contamination at all the stages of the public health engineering cycle even if source treatment is available.

The drainage system can get contaminated from infected people within a building or from adjacent buildings through the public sewer. Drainage traps provide protection against such contamination. However, studies in the healthcare sector have shown that water inside traps can become contaminated and released into the building through bioaerosol. Bioaerosol was identified as the main contributor to the outbreak in the residential complex of Amoy Garden, Hong Kong (1). Thus, it is important to take the same level of precautions and measures in buildings other than healthcare facilities. The PMT is an innovative, seven stages, concept that can be used to identify the risks associated with pathogens and to increase sanitary safety through careful design. It can also be used to evaluate existing systems to improve sanitary safety. Some of the measures proposed in PMT include the selection of water treatment, variable volume storage water tanks, design pressure, physical location of sanitary appliances, sanitary drainage traps and vents and design considerations of wastewater recycling plants. The PMT also provides innovative technologies to improve sanitation environment by automatic methods of disinfection. The human error factor is thus reduced with the aim of achieving the highest level of sanitary safety.

2.0 Pathogens Management Train

2. 1PMT Stage One – Source

2. 1. 1 Water Supply Company Quality of Water

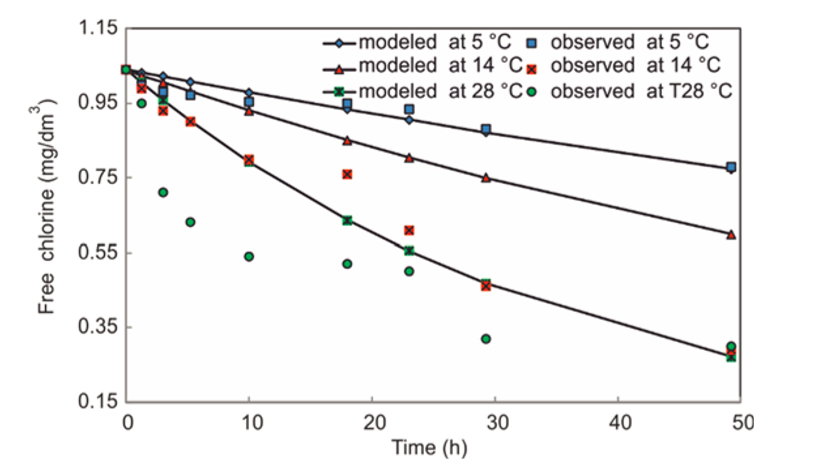

Chlorine disinfection is the most common disinfection system used by Water Supply Companies (WSC). However, the chlorine is consumed in reaction with ammonia and organic compounds in the WSC networks. The free chlorine is also consumed by deposits due to corrosion and biofilm on the inner walls of the pipes (2). As demonstrated in Figure 2, the temperature of water is another factor that affects chlorine decay (3). Therefore, the free chlorine level in water supplied by WSC varies depending on the geographical location of the project. Developments closer to the WSC’s water filtration plant are likely to be supplied with water at a higher level of free chlorine than developments further downstream the WSC’s network.

The suitability of the water quality from the WSC can only be assessed after approved chemical and microbiological test of the water from the site. Water storage tanks are sized from half a day to several days depending on the country and local codes. The storage period affects bacterial growth in water storage tanks.

Figure 2 – Reduction of free chlorine in water at various temperatures (4)

2. 1 .2 Treatment

The level and method of treatment upstream the water storage tank relies on the quality of water from the water supply company, period of storage, and temperature. The table below provides a comparison of disinfection technologies that the designer can refer to in selecting the most appropriate water technology for the project (5).

| Property | Treatment | ||||

|---|---|---|---|---|---|

| Chlorine | Chlorine Dioxide | Ozone | Ultraviolet | Pasteurisation | |

| Disinfection capacity | Medium | Strong | Strongest | Medium | Medium |

| Time required for operation | Hours | Days (dependant upon dead legs usage) | Minutes | Instant | Hours |

| Treats the whole system | No | Yes | No | No | No |

| pH Dependant? | Extreme | None | Medium | Low | No |

| Corrosive? | Yes | Yes | Yes | No | Yes |

| By-products | Trihalomethanes (THMs), adsorbable organohalogens | Chlorine, chlorates, halogens | Possible bromane, perchlorate | Possible nitrite | None, possible sclading |

| Operational temperatures of system | No limitations | No limitations | Not suitable for Domestic Hot Water Systems | Not suitable for Domestic Hot Water Systems | No limitations |

| Maintenance (10-yearly) | Replacement installation | Replacement installation | Replacement installation | Replacement installation | Dependant upon maintenance |

| Maximum water pressure | N/A | 3 bar | N/A | 9.9 bar | N/A |

| Biofilm removal | Not 100% | 100% over time | No | No | No |

| No Smell? | Yes | Yes | Yes | No | No |

| Water hardness problems | Yes | Yes | Yes | Yes | Yes |

Table 1 – Comparison of disinfection technology

2. 2PMT Stage Two – Storage

2. 2 .1Water tank capacity

Water tank storage is typically sized based on N number of days demand. However, the demand is not the same on each day of the week. Consider a school with a normal weekday consumption of 12 m3. The volume of water will be considerably less during weekends or public holidays. This could potentially lead to water being stagnant from 1600 hours on a Friday till 0800 hours on Monday, which equals to 64 hours. Low use during such extended periods will lead to the formation of biofilm inside the water tank surface and will eventually contaminate the distribution network.

The physical dimension of a water storage tank is usually based on the normal demand. However, the storage volume of water can be adjusted to the actual demand to prevent stagnation.

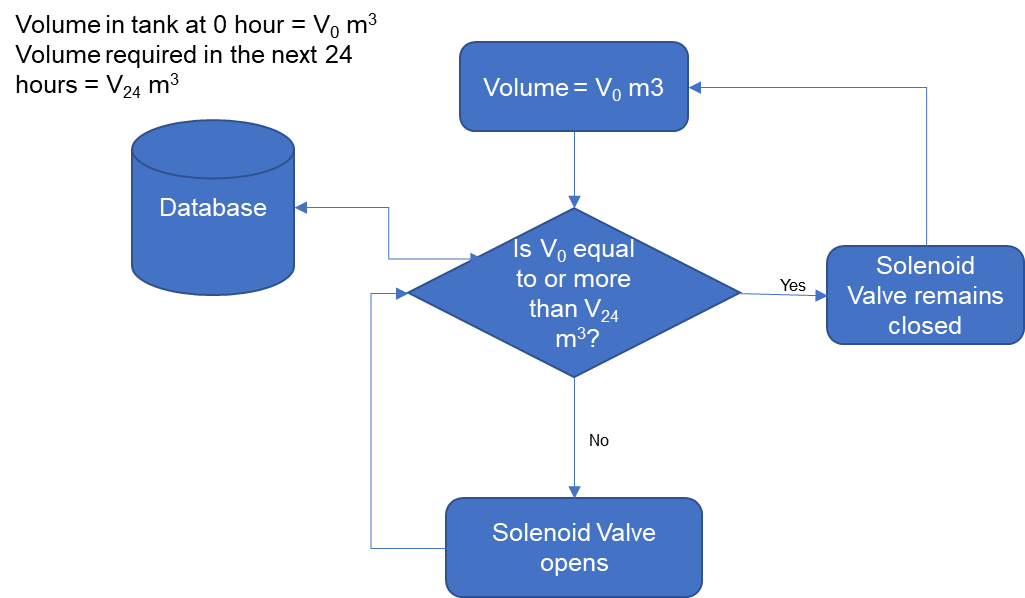

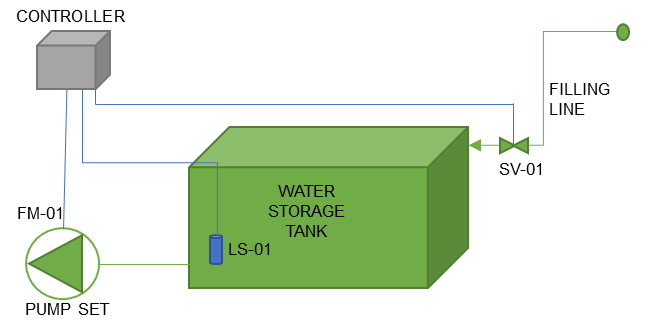

The level can be controlled such that the actual volume stored is based on actual consumption rather than the physical dimension of the water storage tank. As illustrated in Figure 3 and 4, this can be accomplished using existing technologies. A controller can record the actual water demand profile based on the days of the week and period of the year. Level sensors can provide real-time volume of water stored in the tank and a solenoid valve to fill the tank based on actual demand.

Figure 3 – Flow chart of variable water level control

Figure 4 – Sequence of operation

- The Controller records water consumption through the flow meter, FM-01.

- Level Sensor, LS-01, records the volume of water inside the water storage tank.

- The solenoid valve, SV-01, starts or stops the filling of the water storage tank based on input from the controller.

- The controller checks the volume of water inside the water storage tank, V0, and compares it with the volume of water required in the next 24 hours, V24.

- If V0 is more than or equal to V24, then SV-01 remains closed.

- If V0 is less than V24 then SV-01 opens until V0 is equal to V24.

- Step One is repeated.

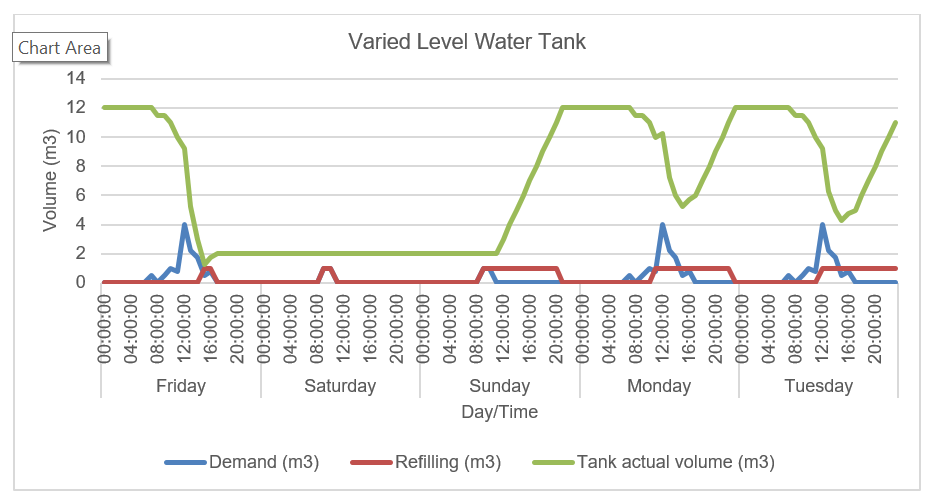

The chart in Figure 5. shows how the volume of water in a water storage tank sized for normal weekdays and weekend demand of 12m3 and 2 m3 respectively can be controlled to reduce the volume stored during the weekend. The green line shows that 12m3 of water is stored during weekdays and the volume is automatically adjusted to 2 m3 during the weekend.

Figure 5 – Varied level of water in storage tank

2. 2. 2 Additional considerations

The following factors should also be considered.

- The shape of the water storage tank should be designed to allow water movement.

- Pump and filling points need to be located to allow movement of water.

- The water tank should not be in direct sunlight to prevent water temperature from rising.

- Water storage tanks should be insulated to prevent a rise in temperature.

- Adequate access should be provided to ease maintenance, cleaning, and periodic disinfection of the water storage tank.

- Devices like sight level indicator tube should not be provided as water in the tube remains stagnant and promotes the growth of bacteria.

2. 2 PMT Stage Three – Distribution

2. 2. 3 System pressure

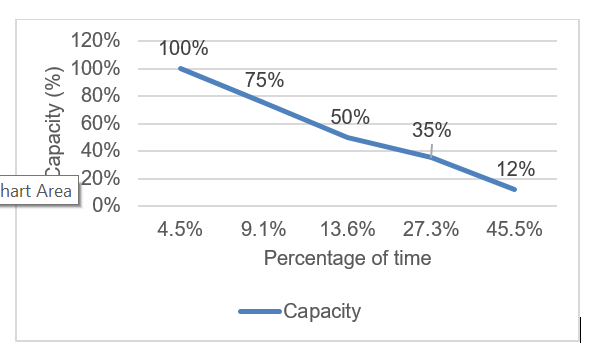

Aerosolization occurs when the water, that the bacteria is growing in, is broken into microscopic water droplets. The emission strength of bioaerosol in high-pressure conditions is statistically greater than that in lower pressure conditions (6). It is important to set the pump pressure correctly in water distribution systems to minimise the release of bioaerosol. Research on pump operation by pump manufacturers shows that pump sets operate at peak capacity during 4.5% of the time only and less than 50% of peak capacity during 86.4% of the time (7). This is illustrated in Figure 6. The pressure of water at the tap is therefore excessive for most of the time.

Figure 6 – Pump capacity versus time

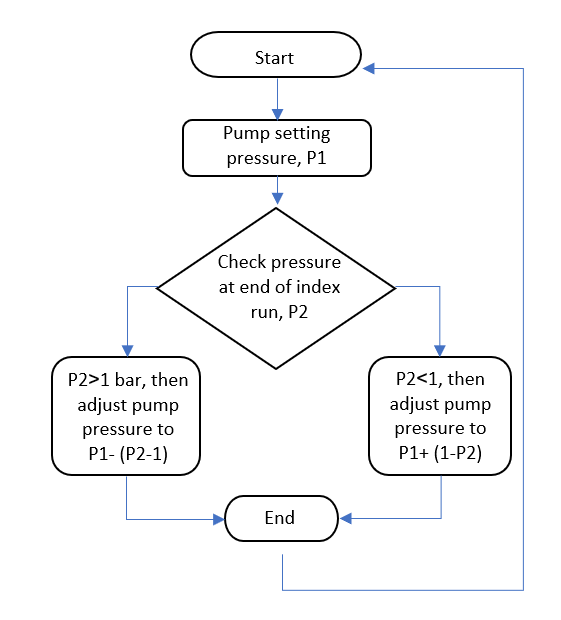

It is recommended to have a variable pump pressure setting so that the pump pressure is automatically adjusted based on the demand of the system. As illustrated by the flow chart in Figure 7, a remote sensor at the end of the index run will allow the pressure to be monitored in real time and the pump setting pressure adjusted based on real time profile. Variable pressure setting does not only prevent excessive pressure at the faucets during low usage but can also help in achieving up to 30% reduction in pumping costs.

Figure 7 – Flow chart of variable pump setting

Pipe configuration

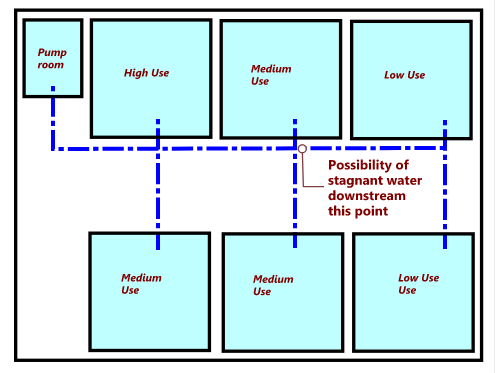

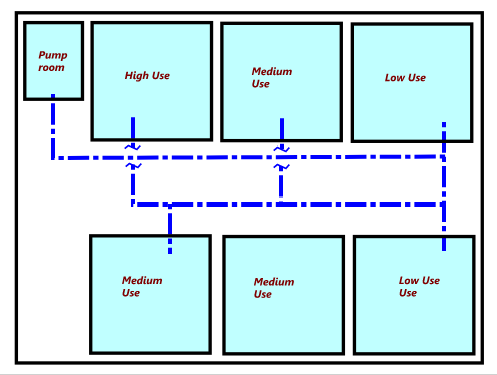

As shown in Figure 8, pipework is generally designed to serve appliances that are physically closer to the pump and then towards the most remote point. This can usually lead to stagnant water when areas of low use are located towards the end of the distribution system. It is recommended to categorise areas into low, medium, and high use. The distribution system can be designed to serve areas of low usage first followed by areas of medium and high use as shown in Figure 9.

Figure 8. Typical distribution system serving areas closer to the pump followed by areas further away.

Figure 9. Modified distribution system serving areas of low use first followed by areas of medium and high use

Additional considerations

The following factors should also be considered:

- Flow splitter valves can also help in providing a minimal flow in sections of the network with low water demand.

- Running pipes in non airconditioned environments, direct sunlight or close to water heaters should be avoided to prevent temperature rise.

- Use of drain points to allow periodical disinfection of pipework and flushing.

- Backflow prevention based on the category of water.

PMT Stage Four – Use

Environment

Water usage in the building is the point where transmission of pathogens from the potable water supply or the drainage is more likely to occur. Bioaerosol is released from both drainage traps and water taps each time an appliance is in use. Döring et al. found that the bacteria Pseudomonas aeruginosa can survive in aerosol for up to 76 minutes depending on the conditions inside the room. It was also found that there is a decrease of 75% within 15 minutes at 36% relative humidity compared to no reduction during the same time at 80% relative humidity. Pseudomonas aeruginosa count was also found to decrease to 50% within 10 minutes with visible light compared to 20% reduction during the same time without visible light (8). Humidity control in washrooms and time delay in Passive Infra-Red (PIR) sensors can help in the reduction of bacterial count.

Location of sanitary appliances and extract

Careful considerations should be taken in locating sanitary appliances. BS 6465 prescribes the activity space, which is the area required in addition to the plumbing fixture for the user to carry out the activity normally associated with the sanitary appliance, of each type of plumbing fixtures (9). Extraction and drainage appliances can be located so that the air path does not cross user’s activity space.

Contamination of taps

The withdrawal of drinking water that is free of pathogenic germs (Legionella pneumophila, Pseudomonas aeruginosa) requires that the withdrawal point (tap) itself is not bacterially contaminated. The outlets of point-of-use filters also become contaminated when they get into contact with bioaerosols from the traps or splash water. Only automatic continuous physical disinfection of sink drains under washbasins and in floor drains and toilet bowls can eliminate this hazard. In the future, it will be necessary to adapt the technical standards to the new findings of aerosol research.

Uses where contamination can occur

Water from potable network should not be used for purposes where contamination can occur without the appropriate backflow protection. Irrigation, washdown, make up water to mechanical plants, water make up to water features or swimming pools are examples where bacteria from the system can enter the potable water network.

PMT Stage Five – Traps

Biofilm forms in drainage traps, for example bottle trap, floor drains and water closets. When water flows through the trap, bioaerosol is released from the trap into the room (10). The bioaerosol can then transmitted to people through the faecal-oral route, breathing or by touch as the bioaerosol settles on the surfaces with time. Pathogens in aerosol can survive and maintain the infectivity for several hours (11). This is often overseen in hospitals and industries and there is a lack of products or solutions to reduce the associated risks. The first self-disinfecting traps were developed 15 years ago and installed in some hospitals but not in the wider industry.

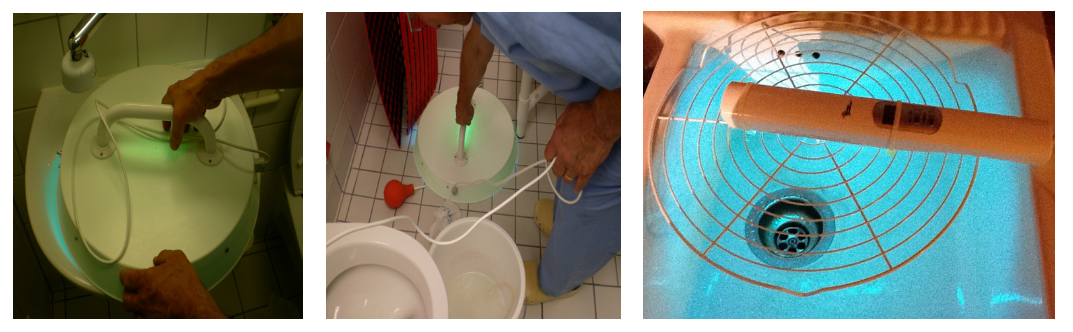

“Find & Kill” Disinfection method

A procedure called the “Find & Kill” method can be used to disinfect the drainage traps. The method involves disinfection using a combination of Sodium Hypochlorite and UV-C light to disinfect the traps (11). The “Find and Kill” method is not available commercially but can be used by building maintenance team to disinfect the drainage system. The frequency of disinfecting the traps depends on the project. The method is effective against all types of pathogens including bacteria, virus, and parasites. However, protection against viral shedding in faecal matter is limited if the infected person is using the toilet regularly after disinfection. In this situation, it is better that the infected person uses dedicated toilet and the traps are disinfected regularly.

This method is mainly used in clinical outbreak situations, where it is important to remove the micro-organism that caused the outbreak from the patient’s environment very quickly and thoroughly. This eliminates the cause of the outbreak and ends the event. UV-C light, as shown in Figure 10, can then be used to maintain the sanitary appliances and floor drains.

Figure 10 – UVC light used for disinfection of WC, floor drain and wash basin

It is possible for contamination to reoccur from the pathogens located in the drainage pipes. However, the installation of a UV-C self-disinfection trap after the “Find and Kill” disinfection procedure provides extended protection by killing pathogens that enter the trap from the drainage pipes.

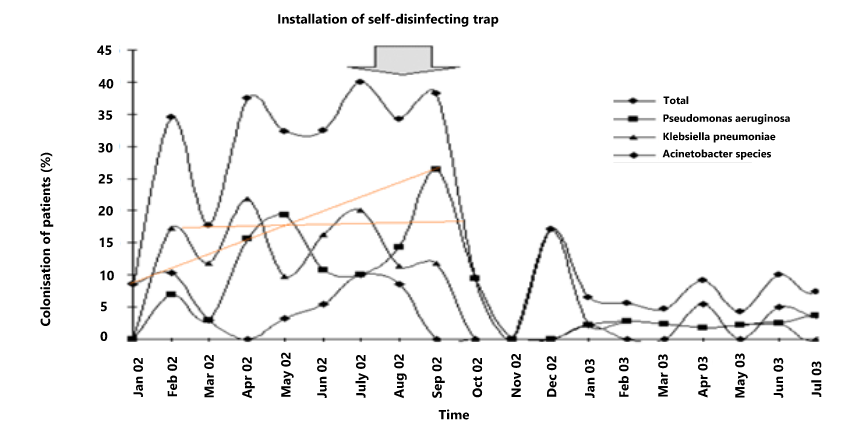

Self-disinfecting trap

Self-disinfection trap can be used for regular disinfection using heat or UV-C light. This has been tested successfully in several hospitals in Germany. The results of the first clinical trial, as shown in Figure 11, show a peak infection of 40% of patients before the installation of the self-disinfecting trap, which decreased to 10% following installation of the disinfection trap (12). Numerous subsequent clinical studies in Germany, the Netherlands and Canada have confirmed these results (13-24).

Figure 11 – Kinetics of contamination (colonization) of patients by water born bacteria before and after replacement of common odour traps by self-disinfecting siphons (12)

Log reduction is the mathematical term used to express the relative number of living microbes that are eliminated by disinfection. Log reduction is equal to log10 (N0 /N)

Where N0 is the colony forming units of the microorganisms before disinfection and N is the colony forming units of the microorganisms after disinfection.

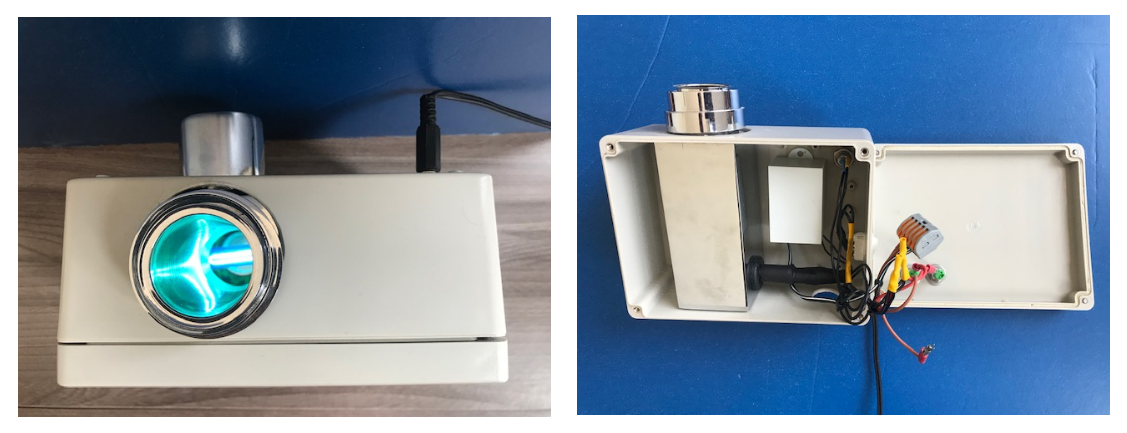

Laboratory tests were carried out and the results show that a trap can produce 6 LOG (99.9999%) reduction in 8 minutes. UV-C Self-disinfecting traps, similar to the one shown in Figure 12, will be available on the market in 2021.

Figure 12 – UVC Self-disinfecting trap prototype for test to be carried out in the Middle East

PMT Stage Six – Drainage

Pathogens can be transmitted between rooms or floors of a building through the drainage ventilation system and ubiquitous microbial biofilms in pipes. This is because all the rooms are interconnected through the drainage network. Disease can spread when traps are dried up because of pressure fluctuations, evaporation, low use of sanitary appliances, or through capillary action when not maintained properly.

Pressure fluctuation in sanitary drainage systems

Wastewater flows inside the sanitary plumbing system resulting in pressure fluctuations, which can empty the water trap seals. Thus, occupants are exposed to harmful bacteria from the drainage system. A properly vented sanitary drainage system helps in overcoming this problem.

Dry traps

A total of 341 cases of SARS were reported at Amoy Gardens, Hong Kong resulting in 42 deaths. As stated by World Health Organisation (WHO), dry U-traps in bathroom floor drains provided a conduit for contaminated sewage droplets to enter households (1). A significant virus load had built up in the sewer system as an increasing number of SARS cases with associated diarrhoea excreted the virus. The latter was aerosolized within the confines of very small bathrooms and may have been inhaled, ingested, or transmitted indirectly by contact with fomites as the aerosol settled (1). Floor drains should be provided only to areas where they will be used regularly. Trap primer valves should be installed where there is a risk of trap seals drying out.

Contamination within multi-occupancy building

High concentrations of infected people in a building can contribute to a higher microbial load in the wastewater system, thus leading to a higher risk of disease spread. Self-isolation during a pandemic can lead to a greater number of infected people in a building and potential system overuse. The use of hospital wards as quarantine areas is also a concern because of the interconnectedness of the whole system (25).

It is therefore recommended to terminate vent stacks directly on the roof and not to vent several stacks using a common vent. It is also recommended to provide adequate ventilation in the sanitary drainage network to prevent the fluctuation of pressure in the stacks. Traps should be fitted to all sanitary appliances. Trap primer valves should be installed where there is a risk of trap seals drying out.

Since the trap is the interface between the wastewater pipes and occupied spaces, the installation of self-disinfecting traps will prevent pathogens found in the wastewater pipes from entering the occupied spaces.

PMT Stage Seven – Recycling and Drainage off site

Drainage off site

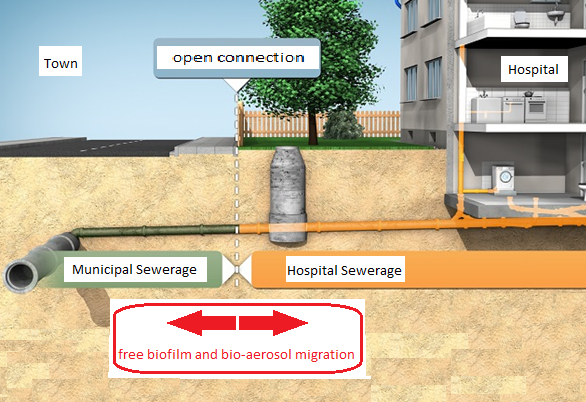

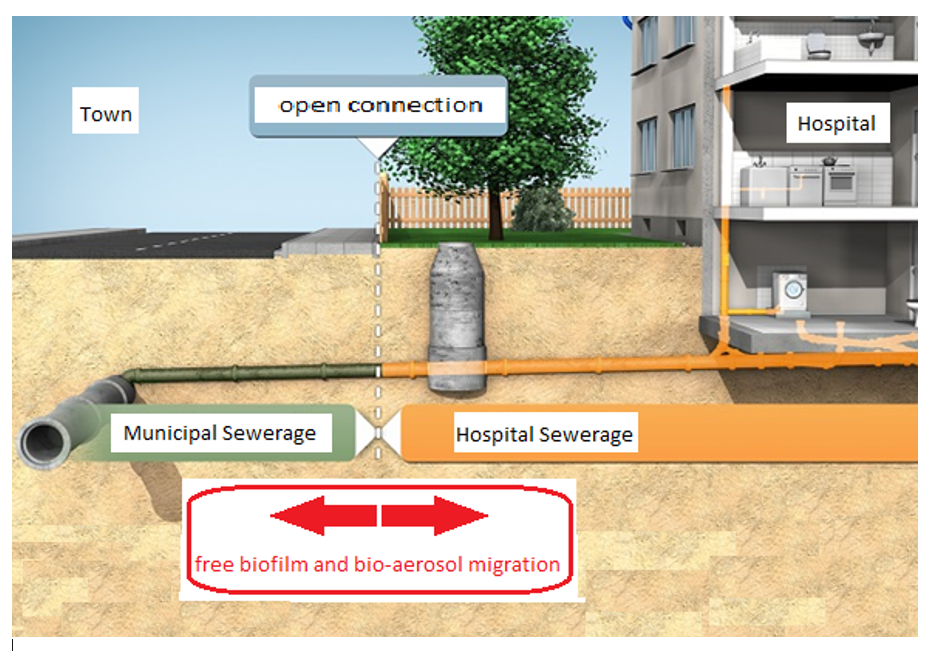

Bioaerosol and biofilm from the public sewer can infect building occupants (Figure 13). It is difficult to prevent this with current technologies. The drainage traps act as the interface between on and off site drainage pipework and the building occupants. One bacterium seeded in the sealing liquid can result in over a million microorganisms overnight which is more than enough to enter an occupied space by aerosol formation during regular use of that sanitary equipment.

Paradoxically, hygienic hand washing can then take place in a cloud of pathogenic microorganisms from the sewage pipe. In 1991, DÖRING et al. first demonstrated this mechanism of transmission in clinical experiments at the University of Tübingen, Germany (8). In the meantime, this process has been proven by hospital hygienists worldwide in clinical studies (13-24). Traps are now accepted as actively emitting germs in hospital hygiene in many countries and methods to eliminate this risk is part of the hygiene standards of clinical risk areas.

Figure 13 – Migration of biofilm and bioaerosol to and from the public sewer

Technologies such as UVC light in combination with periodic chemical disinfection may help but research on their effectiveness has not be carried out. Until such products are developed it is important that careful considerations are given to the design of the building drainage so that bioaerosol is not released inside the building and traps are not depleted. Measures mentioned in Stage Five and Six of PMT, like adequate sanitary vent, trap primer and self-disinfecting trap can protect building users from risks associated with contamination from the municipal sewer.

Wastewater Treatment Plant

Studies conducted on wastewater treatment plant bioaerosol concentration, identified operational control measures to reduce the level of bioaerosol production from wastewater treatment plant processes. Deployment of casing or additional covering of processes associated with generation of high levels of bioaerosols has been identified to reduce bioaerosol exposure levels of workers (26). Actions taken to reduce formation of odours by outdoor wastewater treatment plant (i.e., covering outdoor grit tanks and primary settling tanks) are associated with measured reductions of bioaerosols (26). Based on evaluations to determine emissions of bioaerosols relative to unit volumes of wastewater, Bauer et al. (2002) recommended that reductions in the surface area of the aeration tank could reduce the flux of bioaerosol emissions (27). In an approach designed to effectively limit the surface area of bulk wastewater exposed to air, Hung et al. reported E. coli bioaerosol reductions between 50% and 100% when polystyrene balls with diameters sizes of 1.9 to 4.7 cm were placed at the water surface of a laboratory-scale tank (28).

Recent works of SARS-CoV-2 in sewage system

Coronaviruses (CoVs) are a family of viruses pathogenic for humans and animals associated to respiratory and gastro-intestinal infections. CoVs were used to be considered as minor pathogens as they were responsible of common cold or respiratory infections in immunocompetent people. However, the emergence of novel COVID-19 has caused almost 3.8 million deaths globally.

CoVs are mainly transmitted through respiratory droplets. However, as for SARS and MERS, SARS-CoV-2 RNA has been detected in stool samples from patients exhibiting symptoms of COVID-19 and from asymptomatic carriers. The duration of viral shedding has been observed to vary among patients with means of 14 to 21 days (29). PMT procedures, described in Section 2.6 and 2.7 can help in reducing the risk of COVID-19 spread from wastewater.

Proposed PMT procedures

The procedures in Table 3 can be used by designers as a guidance to reduce the risks of disease transmission in public health engineering systems.

| Item | PMT Stage | Description | Checked (Yes/No) | Remarks |

|---|---|---|---|---|

| 1 | 1 | Testing of incoming water? | ||

| 2 | 1 | Additional treatment required? (Description) | ||

| 3 | 2 | Water demand profile checked? | ||

| 4 | 2 | Varied level water storage tank provided? | ||

| 5 | 2 | Shape of water storage tank to promote movement of water? | ||

| 6 | 2 | Location of suction and filling point to promote water movement? | ||

| 7 | 2 | Exposure to sunlight or high temperature? | ||

| 8 | 2 | Adequate access for maintenance? | ||

| 9 | 2 | Drain points? | ||

| 10 | 2 | Any device like sight water level indicator that creates stagnant water spot? | ||

| 11 | 3 | Varied Setting Pressure of pump set? | ||

| 12 | 3 | Measures to reduce stagnant water in low water demand portion (flow splitter valve, pipework configuration to feed low water demand areas before high frequency use appliances? | ||

| 13 | 3 | Pipework exposed to sunlight, rooms at high temperature or unconditioned space? | ||

| 14 | 3 | Drain points? | ||

| 15 | 3 | Any direct connection to equipment that can cause contamination like irrigation and chilled water make-up pipe? | ||

| 16 | 4 | Location of sanitary appliances in direct path of extract air? | ||

| 17 | 4 | Location of floor drains at a reasonable distance from kitchen sinks? | ||

| 18 | 4 | Humidity control? | ||

| 19 | 5 | Material of traps to allow periodic chemical disinfection? | ||

| 20 | 5 | Accessibility to traps allow disinfection (UV, chemical)? | ||

| 21 | 5 | UV-C Traps provided? | ||

| 22 | 5 | Removable floor drain traps? | ||

| 23 | 6 | Adequate venting provided in the network to prevent pressure fluctuation? | ||

| 24 | 6 | Replenishment of low use floor drains (manually or trap primer valve)? | ||

| 25 | 6 | Backwater valve to prevent contamination of sensible areas? | ||

| 26 | 7 | Location of recycling plant? (proximity to sensible areas like food preparation) | ||

| 27 | 7 | Adequate ventilation of the foul water network? | ||

| 28 | 7 | Any risk of contamination from the public sewer? Any development with potential contaminated sewer in proximity? (Hospitals, Food Processing) | ||

| 29 | 7 | Is the wastewater treatment plant covered? | ||

| 30 | 7 | Location of wastewater treatment proximity to sensitive areas? | ||

| 31 | 7 | Odour control installed in wastewater treatment plant? |

Table 2 – Proposed PMT procedure

3.0 Conclusion

Contamination of water and spread of disease can occur at all the stages of the plumbing cycle. There are treatment plants on the market that can help in reducing the risk of contamination or bacterial growth in the public health engineering systems. However, these products provide disinfection at the point of installation and to a certain degree downstream of the installation. Contamination can still occur downstream of the filtration plant if the system is not engineered correctly. Firefighting, irrigation, Low Temperature Hot Water (LTHW) and chilled water systems are not covered in this paper, but these systems pose potential risks. Firefighting water remains stagnant for over a long period of time within the network and generally maintenance staff may be exposed to contaminated water during the mandatory maintenance operation. A hygiene policy should be in place for people accessing and exposed to these systems. Irrigation system, on the other hand is an open system and is used daily. However, the open network is directly exposed to topsoil which can cause ingress of bacteria and formation of biofilm inside the network. Sub soil irrigation can reduce the risk of contaminated water to come into direct or indirect contact to humans. Closed loop systems like LTHW and Chilled water can also become contaminated and direct connection to potable water systems should not be provided. A break tank should be provided to provide make-up water to these systems. Like firefighting system, there should be a hygiene policy for closed loop system operators

The PMT identifies the risks at all the stages based on previous laboratory and field research. The solution generally consists of selecting the right existing technology, modify existing systems or control and making use of new technologies. Technologies from the healthcare sector can also be used in commercial buildings and to future proof buildings against any future outbreak that can occur in the water installation systems.

The proposed PMT procedures can be used as a guideline for new installation. However, the designer should consider all possible exposure pathways within the project or from the surrounding developments. It is also important for facilities managers to monitor existing buildings and to carry out periodic tests to find traces of contamination inside the plumbing systems. Initial evaluation can be carried out using the PMT. Laboratory tests of water can be carried out at the different stages of the public health engineering cycle. Based on the results, the measures described in the PMT can be incorporated. The PMT is a useful novel tool to provide a safe sanitary system in both new and existing buildings.

References

(1) World Health Organisation. Consensus document on the epidemiology of severe acute respiratory syndrome (SARS). Available from: https://www.who.int/csr/sars/en/WHOconsensus.pdf. [Accessed on 26.04.2021]

(2) Zacheus O, Lehtola M, Korhonen L, Martikainen P. Soft deposits, the key site for microbial growth in drinking water distribution networks. 2001.

(3) Nagatani T, Yashuhara K, Murata K, Takeda M, Nakamura T, Fuchigami T, et al. Residual Chlorine Decay Simulation in Water Distribution System. 2008.

(4) Saidan M, Rawajfeh, Nasrallah S, Meric Sureyya. Evaluation of factors affecting bulk chlorine decay kinetics for Zai water supply system in Jordan. 2017.

(5) Angus P, CIBSE Guide G Water Services and Utilities, 2014.

(6) Lai ACK, Tan TF, Li WS, Ip DKM. Emission strength of airborne pathogens during toilet flushing. 2018.

(7) Monga R. Email sent to Ashveen Jeetun. 09 June 2020.

(8) Döring G, Ulrich M, Müller W, Bitzer J, Schmidt-Koenig L, Münst L, et al. Generation of pseudomonas aeruginosa aerosol during handwashing from contaminated sink drains, transmission to hands of hospital personnel, and its prevention by use of a new heating device. 1991.

(8) Biorec, Schluttig A. Transmission of SARS-CoV-2 in aerosols from water traps in sanitary areas of public institutions and business premises. Available from: https://biorec.de/?lang=en. [Accessed 17 January 2021].

(9) British Standard Institutions. BS 6465-2:2017. Sanitary installations Space recommendations – code of practice. 2017

(10) Schluttig A. Email sent to Ashveen Jeetun. 25 June 2020.

(11) Schluttig A. Email sent to Ashveen Jeetun. 16 January 2021.

(12) Sissoko B, Sütterlin R, Stöber K, Schluttig A. Prävention nosokomialer Infektionen aus Waschbecken-Abläufen, HygMed. 2004; 29 (12): 12-16.

(13) Sissoko B, Sütterlin R, Blaschke M, Flicker, J. und Schluttig, A. Infektionsreservoir Geruchsverschluss: Prävention nosokomialer Infektionen, HygMed. 2004; 29 (12): 451-455.

(14) Sissoko B, Sütterlin R, Blaschke M, Stefaniak S, Daeschlein G, Kramer A. Emission von Bakterien aus Geruchsverschlüssen, HygMed. 2005; 30 (4):72-76.

(15) Sissoko B, Sütterlin V. DGKH-Kongress. Berlin. May 2005.

(16) Kramer A, Daeschlein G, Niesytto B, Sissoko B, Sütterlin R, Blaschke M, Fusch C. Contamination of sinks and emission of nosocomial gramnegative pathogens in a NICU-outing of a reservoir as risk factor for nosocomial colonization and infection. Umweltmed.Forsch.Prax. 2005;10(5).

(17) Kramer A, Daeschlein G, Weber U. Experiences with water safety plan in an university hospital over one year including prevention of bacterial emission from sink drains. DOSCH Symposium, Goldegg. Österreich, 2006.

(18) Dyck A, Hospital Water safety Plan, Greifswald, Managemnent & Krankenhaus. 07/2006.

(19) Würstl B, Rieger C, Bader L, Kramer A, Heesemann J. Emerging multiresistant Pseudomonas aeruginosa and its hidden reservoirs in hospitals – molecular studies of a nosocomial outbreak in a high risk area, 9. Ulmer symposium “Krankenhausinfektionen” DGKH. 2011.

(20) Schneider H, Geginat G, Hogardt M, Kramer A, Dürken M, Schroten H, Tenemann T. Pseudomonas aeruginosa outbreak in a pediatric oncology care unit caused by an errant jet into contaminated sinks. The Pediatric Infectious Disease Journal, Volume 31, Number 6, 648-650, June 2012.

(21) Fusch C, Pogorzelski D, Main CL, El Helou S, Mertz D. Self-disinfecting sink drains reduce Pseudomonas aeruginosa bioburden in a neonatal intensive care unit. Acta Paediatrica. 2015; 104: 344-349,

(22) Wolf I, Bergervoet PWM, Sebens FW, Van Den Oever HLA, Savelkoul PHM, Van Den Zwet WC. The sink as a correctable source of extended-spectrum ß-lactamase contamination for patients in the intensive care unit. Journal of Hospital Infection. 2014; 87: 126-130,

(23) Willmann M, Bezdan D, Zapata L, Susak H, Vogel W, Schröppel K, Liese J, Weidenmaier, C, Autenrieth IB, Ossowski S, Peter S. Analysis of a long-term outbreak of XDR Pseudomonas aeruginosa: a molecular epidemiological study. Journal of Antimicrobial Chemotherapy. 2015; 70:1322-1330,

(24) De Jonge E, De Boer MGJ, Van Essen EHR, Dogterom-Ballering HCM, Veldkamp KE. Effects of a disinfection device on colonization of sink-drains and patients during a prolonged outbreak with multiresistant Pseudomonas aeruginosa in an ICU. Journal of Hospital Infection. Available from: https://doi.org/10.1016/j.jhin.2019.01.003. [Accessed on 26.04.2021]

(25) Gormley M, Aspray TJ, Kelly DA. COVID-19: mitigating transmission via wastewater plumbing systems. Available from: https://www.thelancet.com/journals/langlo/article/PIIS2214-109X(20)30112-1/fulltext. [Accessed on 26.04.2021]

(26) Fernando, NL, Fedorak PM. Changes at an Activated Sludge Sewage Treatment

Plant Alter the Numbers of Airborne Aerobic Microorganisms. 2005.

(27) Bauer H, Fuerhacker M, Zibuschka F, Schmid H, Puxbaum H (2002). Bacteria and Fungi in Aerosols Generated by Two Different Types of Wastewater Treatment Plants. 2002.

(28) Hung HF, Kuo YM, Chien CC, Chen CC. Use of Floating Balls for

Reducing Bacterial Aerosol Emissions from Aeration in Wastewater Treatment

Processes. 2010.

(29) Randazzo W, Truchado P, Cuevas-Ferrando E, Simon P, Allende A, Sánchez G. SARS-CoV-2 RNA in wastewater anticipated COVID-19 occurrence in low prevalence area. Water Research. 2020

Acknowledgements

I would like to thank Dr. Alexander Schluttig for his valuable help. He has been sharing his experience and knowledge, especially on the drainage portion, since last year when the concept of PMT was at its initial phase.

I am also grateful to Dr. Ryad Soobhany from Heriott-Watt University who kindly accepted to review the paper and also provided some useful comments.

I would also like to thank my colleagues Gavin Loy, John Myers and Pedro Cadima from BuroHappold in providing some useful comments as experienced building services engineers.

Total views : 36018

Total views : 36018